Our Production

Our advantages

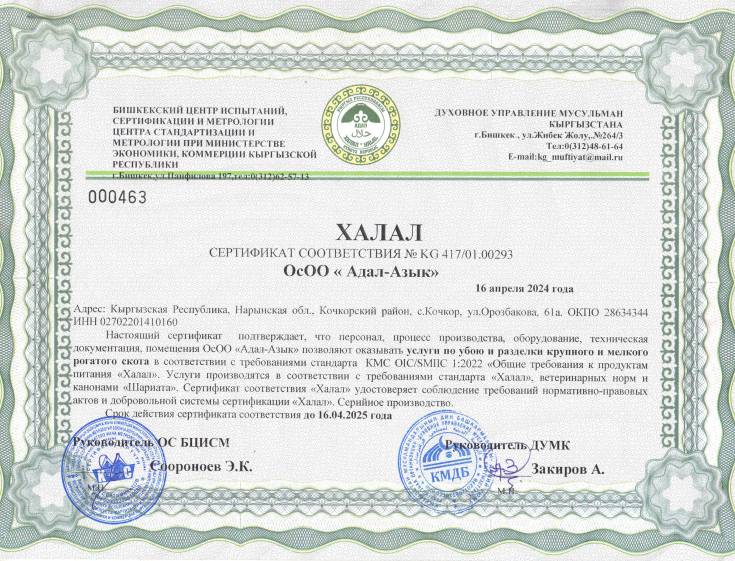

Compliance with Standards

In 2017, we launched a “smart” meat processing plant and a slaughterhouse that meet highest international food safety standards. Our production is certified by TÜV Thüringen e.V. and complies with the requirements of ISO 22000:2005, ISO/TS 22002-1:2009, and FSSC 22000, ensuring the safety and quality of all our products. We also place great importance on adhering to religious principles. All our raw materials and suppliers, the slaughterhouse and production processes fully comply with halal standards. This is confirmed by the Spiritual Administration of Muslims of Kazakhstan and Kyrgyzstan, as well as the Halal Industry Development Center of Kyrgyzstan.

Laboratory

Our production facility is equipped with its own laboratory, which plays a key role in ensuring safety of our products. Comprehensive analyses, including microbiological, physicochemical, and organoleptic tests, are conducted daily. The laboratory monitors the quality of not only raw materials and finished products but also the cleanliness of equipment, premises, water, and hands and uniforms of staff. Our laboratory is accredited according to the GOST ISO/IEC 17025 standard, which confirms its high qualification level and reliability of results.

Production Facility

Our production facility was designed considering all production processes and safety requirements. All potential sources of contamination and hazards to food products were considered. The internal layout is arranged to prevent cross-contamination of materials, products, and personnel. The materials used in the construction are highly resistant to aggressive environments, ensuring the durability and safety of the building.

Support Systems

The systems providing drinking water, air, and ventilation meet the strictest standards and microbiological requirements. The quality of air and water is constantly monitored by the laboratory to minimize the risk of contamination. Ventilation systems are designed to effectively separate "dirty" and "clean" zones and prevent cross-contamination.

Equipment

To achieve high product quality, we use equipment from leading global manufacturers. Our production lines are equipped with advanced control and automation systems, ensuring precision and efficiency in the process. We constantly improve our equipment and technologies to increase quality and production efficiency while staying current with the latest trends.

QR-Code Traceability System

The QR-code traceability system, specifically designed for Toyboss, is a unique solution in the Kyrgyzstan food industry and is also unique in CIS countries. It allows tracking of each product unit at all stages—from the slaughterhouse to the store shelf. By scanning the QR code or batch number, we can access the following information:

- Product origin: where the raw material came from and which components were used in its production.

- Production process: technical details of each production stage, from slaughter to packaging.

- Quality control: results of laboratory tests and quality checks of the product.

- Distribution: sale points where the products from a particular batch were delivered.

Sustainable Production Practices

In addition to increasing production efficiency, we always strive to reduce its negative impact on the environment. To do this, we implement modern technologies and innovative solutions aimed at optimizing processes and improving environmental sustainability. For example, our production facility has its own water treatment system, which effectively removes impurities and contaminants from wastewater treatment and minimizes environmental impact. We have also implemented a heat energy recovery system, allowing us to use waste heat to heat water or rooms. This not only increases the energy efficiency of production but also significantly reduces energy consumption and harmful emissions into the environment.

Slaughterhouse

In 2017 Toyboss launched the first modern slaughterhouse in Kyrgyzstan. The slaughterhouse complies with Kyrgyz legislation and the technical regulations of the Customs Union, the principles of the HACCP food safety control system, ISO 22000:2005, ISO/TS 22002-1:2009 and FSSC 22000. Slaughtering is carried out with strict adherence to halal principles and is certified by the Spiritual Administration of Muslims of Kyrgyzstan and KMS (Kyrgyz National Standards). The capacity of the modern slaughterhouse is 22 tons of live weight per shift.

Pre-Slaughter Holding

To guarantee the high quality and safety of our products, we pay considerable attention to the management of livestock before slaughter. We have a specific pre-slaughter holding capacity for up to 150 heads of livestock. Each animal is subject to a thorough inspection and maintained on an ecologically clean diet for 21-30 days prior to slaughter to ensure optimal health and quality. Animals that successfully pass our health checks are moved to a day-long holding facility where blood samples are taken before they proceed to the slaughterhouse. If an animal fails this health assessment, it is transferred to a quarantine area for further medical treatment and monitoring, ensuring that only healthy livestock is processed.

KY

KY RU

RU EN

EN